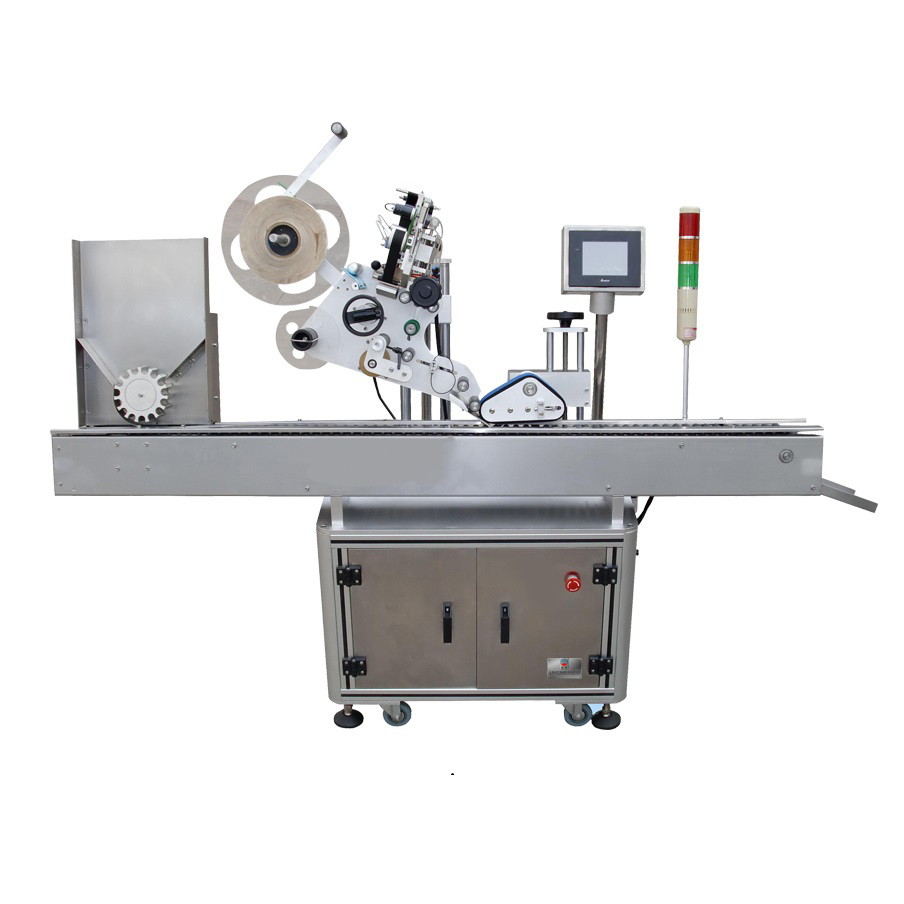

Achieve automatic attachment of adhesive labels or adhesive films on the circumferential surface and small conical surface of the product.Purpose: High efficiency, accurate positioning, good quality, and high stability of product labeling and film attachment; avoiding a series of problems such as low efficiency, skewed, bubbled, wrinkled, or irregularly positioned manual labeling and film attachment; effectively reducing product costs, improving product identification aesthetics, and enhancing product competitiveness.

Applicable Labels: Adhesive labels, adhesive films, electronic supervision codes, barcodes, etc.

Applicable Products: Small products requiring labeling or film attachment on the circumferential surface or small conical surface.

Applicable Industries: Widely used in industries such as daily chemicals, electronics, pharmaceuticals, hardware, plastics, cosmetics, etc.

Application Examples: Labeling of solid glue bottles, insulin bottle labeling, pen shaft labeling, etc.

|

project

|

parameter

|

|

Machine size

|

2000(L)×1000(W)×1600(H)mm

|

|

Labeling speed

|

30-400 pieces/min (depending on the size of the labeled object and the length of the label)

|

|

Label height

|

25-95 mm

|

|

Applicable bottle diameter

|

12-24mm

|

|

Label height

|

20-90mm

|

|

Label length

|

25-80mm

|

| Labeling accuracy | ±0.5mm (excluding the error between the attached object and the label) |

| Paper roll inner diameter (diameter) | 76mm |

| Paper roll outer diameter | 380mm |

| power supply | 220V 1.5kw 50/60HZ |

| Air source for printer | 5Kg/c㎡ |

1. Adopts a horizontal labeling method, comprehensively achieving full-circle, semi-circle labeling for round bottles and small tapered bottles.

2. Labeling speed, conveyor speed, and bottle separation speed can be continuously adjusted, facilitating adjustments by production personnel according to actual needs.

3. Equipped with automatic bottle separation function, achieved through a bottle separation wheel, ensuring safe and efficient bottle separation. Switching production to bottles of different diameters only requires simple replacement of the bottle separation wheel.

4. High labeling positioning accuracy and good stability, resulting in smooth, wrinkle-free, and bubble-free labeling.

5. The mechanical adjustment parts are structured in combination with clever design for label winding, allowing for convenient fine-tuning of labeling positions with 6 degrees of freedom (after adjustment, it can be completely fixed), simplifying and saving time during transitions between different products and label winding.

6. Features automatic detection to prevent missed labeling, ensuring labels are applied correctly and effectively preventing issues caused by label winding.

7. Equipped with fault alarm function, production counting function, power-saving function (automatically switches to power-saving standby mode when there is no production within the set time), production number setting prompt function, and parameter setting protection function (parameter settings are managed by permissions).

8. Optional features include: ① Hot stamping/inkjet coding function ② Automatic material receiving function (consideration should be made in conjunction with the product) ③ Addition of labeling head ④ Circular perimeter labeling function ⑤ Other functions (customized according to customer requirements).

Shanghai Shengzhe Mechanical Technology Co., Ltd. was founded in 2003 and is a professional manufacturer integrating production, engineering, and trade. After 10 years of forging, it has gradually formed packaging equipment with pharmaceuticals, food, cosmetics, and other products as its main products: high-speed cartoning machines, transparent film three-dimensional packaging machines, transparent film bundling machines, integrated box opening, packing, and sealing machines, fully automatic unmanned bundling machines, as well as multifunctional pillow-type packaging machines, labeling machines, wrapping machines, wrapping machines, filling and sealing machines, extrusion sheet machines, paper bowl machines, bowl sticking machines, disc box machines, capping machines, cup stacking machines, molds, and other diverse series of electromechanical fully automated machinery and equipment.