Filling And Capping Machine

-

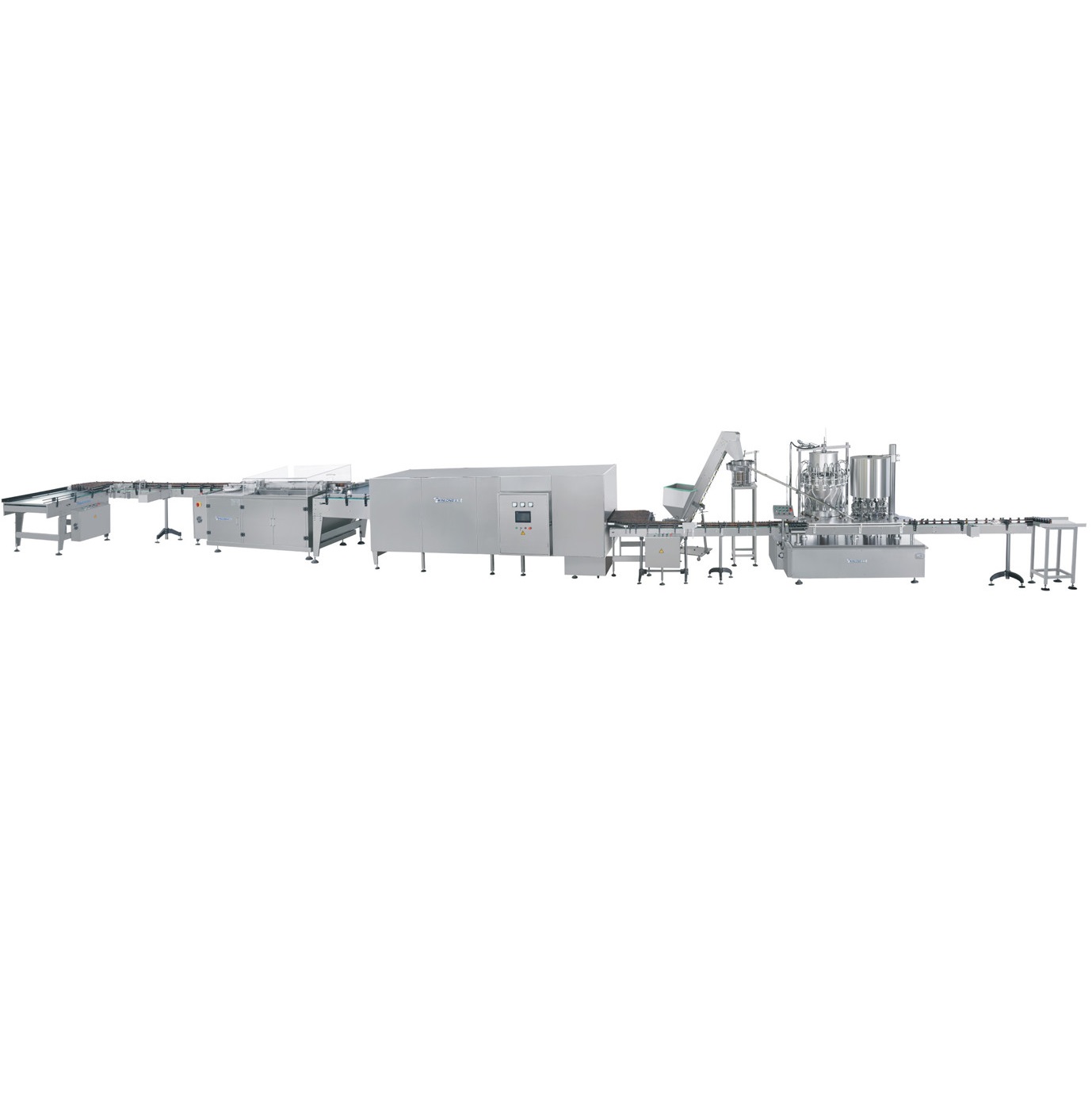

- SZKJ-Full Automatic Oral Liquid Filling Production Line

The fully automatic oral liquid bottling production line belongs to the medical production line series and is suitable for the production of oral liquid bottles of different sizes, such as 5-30ml. It can complete the linked operation of processes including rinsing, cleaning, flushing, air charging, drying sterilization, cooling, filling, and capping during pharmaceutical production.

-

- SZKJ-Fully Automatic Syringe Bottling Production Line

The fully automatic syringe bottling production line belongs to the medical production line series, suitable for the production of syringes of different sizes such as 5-30ml. It can complete a series of process steps in pharmaceutical production, including rinsing, cleaning, flushing, filling, drying, sterilizing, cooling, filling, and capping of ampoules.

-

- SZKJ-LP200 fully automatic bottle unscrambler

fully automatic bottle unscrambler Manually pour disorganized bottles into the bottle storage box → Bottle sorting → Properly aligned bottles proceed to the next packaging process.

-

- SZKJ-LP50/1000 fully automatic bottle unscrambler

The automatic bottle unscrambler is suitable for automatic transmission of round bottles and square bottles, such as conveyor belts connected to labeling machines, filling machines, and capping machines, to automatically deliver bottles and improve efficiency; it can be used at the middle connection of the assembly line as a buffer platform to shorten the length of the conveyor belt.

-

- SZKJ-Automatic in-line capping machine

This model is remodeled and designed based on absorbing advanced domestic and foreign technologies. Its characteristics: small size, simple transmission mechanism, smooth operation, low noise, high efficiency, wide adjustment range, beautiful appearance and other advantages.

Each key transmission mechanism of the capping machine adopts advanced frequency converter control technology. The speed of each part can be accurately controlled to achieve satisfactory use results. The cap sorter uses imported photoelectricity to remove reverse caps, so that the positive cap rate reaches more than 99%.

-

- SZKJ-800 fully automatic capping machine

This model is remodeled and designed based on absorbing advanced domestic and foreign technologies. It integrates automatic capping, automatic capping, and automatic capping. It has the following advantages: small size, simple transmission mechanism, smooth operation, low noise, high efficiency, wide adjustment range, and beautiful appearance.

Each key transmission mechanism of the capping machine adopts advanced frequency converter control technology. The speed of each part can be accurately controlled to achieve satisfactory use results. The cap sorter uses imported photoelectricity to remove reverse caps, so that the positive cap rate reaches more than 99%.

-

- SZJ-XC01 multifunctional manipulator capping capping machine

This machine is designed for various types of container capping operations; it is beautiful, not easy to damage the caps, and fully complies with cGMP standards. The operation is simple, and the capping operations of different containers can be changed in a short time, achieving the cost-effectiveness of using one machine for several applications. It is suitable for automatic capping operations in general chemical industry, pharmaceutical industry, food, cosmetics and cleaning supplies.

-

- SZKJ-C01 fully automatic filling and capping machine

This machine is capable of filling, inserting inner plugs/bolts and sealing outer lids. It is specially used for small-volume liquid packaging operations, especially for the hardware facilities of sterile rooms, which saves and streamlines energy consumption. And using PLC logic controller and various detection and induction devices, filling, plugging/stopping and sealing the outer cover are completed in one go, fully complying with cGMP standards. Suitable for automatic packaging of eye drops, water-based injections, cosmetics, flavors, etc.

-

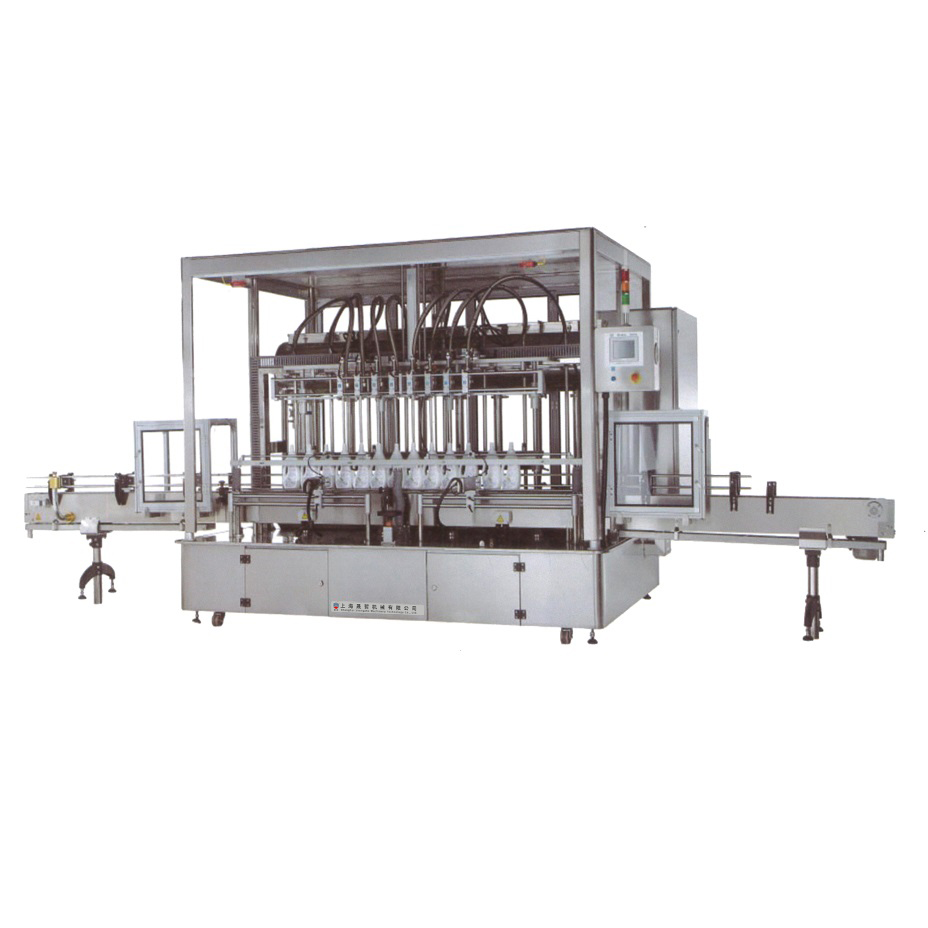

- SZKJ-Linear rotor pump filling machine

This equipment adopts advanced servo motor-controlled volumetric filling technology. To change any filling specification, you only need to modify the parameters on the touch screen. It can make substantial overall adjustments to the filling volume of 12 heads at the same time, and can also adjust the filling volume of a single head. The metering of the filling head is fine-tuned.

Applicable materials: Quantitative filling of liquids, emulsions, suspensions, edible oils, lubricating oils and other non-air-containing fluids and semi-fluids. It is an ideal packaging equipment for agrochemical, daily chemical, food, pharmaceutical and other industries.

-

- SZKJ-fully automatic canning and sealing machine

The fully automatic filling and sealing machine is suitable for filling and sealing metal hoses in the pharmaceutical, food, cosmetics, daily chemical and other industries. It can smoothly and accurately inject various pasty, ointment, viscosity fluid and other materials into the hose, and complete folding and sealing, batch number, production date, etc. The machine adopts Taiwan touch screen and PLC control system to achieve contactless operation, intuitive and convenient, and reliable operation.

-

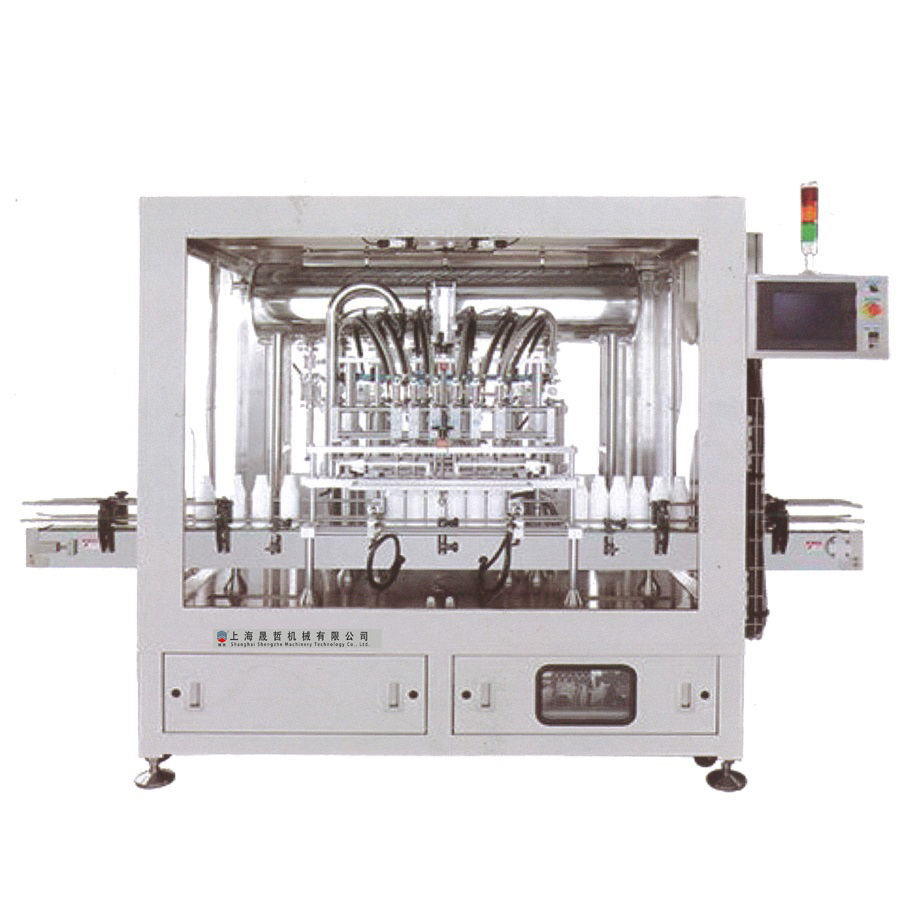

- SZKJ fully automatic piston liquid filling machine (full servo system)

This equipment adopts advanced servo motor controlled volumetric filling technology. To change any filling specification, you only need to modify the parameters on the touch screen.

Easy to learn, easy to adjust, wide range of applications, strong stability, etc.

Applicable materials: Quantitative filling of liquids, emulsions, suspensions, edible oils, lubricating oils and other non-air-containing fluids and semi-fluids. It is an ideal packaging equipment for agrochemical, daily chemical, food, pharmaceutical and other industries.

-

- SZKJ-Conveyor type bottle loading machine

Push the entire plate of bottles with their mouth upwards onto the conveyor line to transport the bottles, reducing labor